FIBC Guide

The first ever FIBC Price Calculator Tool

FIBC Bulk Bag Estimated Price Calculator Tool

Estimate the cost of your bulk bag!

Use this intuitive savings calculator to estimate the cost of your bulk bag! The larger the volume, the greater the savings. Please note, this calculator offers an estimated USD EXW batch price per bag only. Prices fluctuate. For a more accurate quote, kindly contact us directly.

Types of Bulk Bags

Type A

Type A FIBCs are constructed from plain-woven polypropylene and other non-conductive fabrics. These bags are prone to static electricity buildup as products move or rub against the inside surface during filling or emptying. However, Type A FIBCs offer no static protection.

These bulk bags are suitable for transporting non-flammable products, but should not be used in environments where flammable solvents or gases are present. For safety, it’s essential to ensure that Type A FIBCs are only used with non-flammable materials.

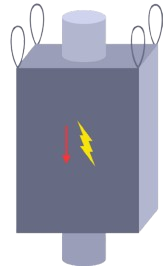

Type B

Type B FIBCs are made from plain-woven polypropylene or other non-conductive materials, similar to Type A bags. However, unlike Type A bags, Type B FIBCs are designed with materials that have a low breakdown voltage, preventing dangerous propagating brush discharges. While they reduce the risk of such discharges, Type B bags do not actively dissipate static electricity, so they are not considered anti-static.

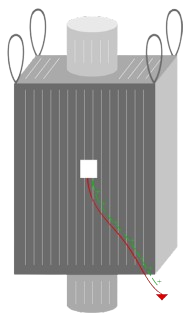

Type C

Type C FIBCs, also known as conductive or groundable bulk bags, are made from non-conductive polypropylene fabric interwoven with conductive threads. These threads must be electrically interconnected and connected to a designated grounding wire during filling and discharging. Proper grounding is essential for the safe use of Type C FIBCs, as it prevents the buildup of static electricity during the filling and discharging process.

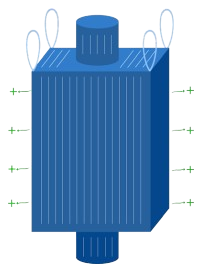

Type D

Type D FIBCs are made from anti-static and static dissipative fabrics, designed to prevent incendiary sparks, brush discharges, and propagating brush discharges without the need for a grounding connection. These bulk bags are ideal for safely packaging combustible products and handling materials in combustible or flammable environments.

Bulk Bag Liners

Lay-flat liners

Lay-flat polyethylene liners are the most common type of liners used in bulk packaging. These cylindrical liners are open at the top and heat-sealed at the bottom. To discharge the product, the heat-sealed liner must be cut. Lay-flat liners are often pre-inserted into bags or sold separately in rolls for easy insertion.

Form-fit liners

Form-fit bulk bag poly liners are custom-designed to perfectly match the shape of the bag, including the spout inlet and outlet. These liners enhance bag performance by protecting contents from contamination during processing, storage, and transportation.

Form-fit liners promote consistent filling and discharging, as they lack folds, pleats, or other obstacles that can slow product flow. They can be either permanently attached to the bag or easily removed after use. Like lay-flat liners, form-fit liners offer key benefits such as an oxygen barrier, moisture barrier, chemical resistance, anti-static properties, and superior strength.

Tubular liners

Tubular liners are similar to standard gusset liners, sharing the same polyethylene material and being pre-inserted into the bag during manufacturing. The main structural difference lies in the bottom of the liner. In a standard gusset liner, the bottom is sealed, requiring the liner to be cut during discharge. In contrast, tubular liners feature an open bottom, allowing the liner to be fed through the spout during production. This design eliminates the need for cutting when discharging the bag.

Aluminium foil liners

Form-shaped aluminium liners, also known as foil liners, enhance the filling, discharging, handling, and stability of bulk bags. These liners provide exceptional moisture, oxygen, and UV protection, making them compatible with a wide range of bags.

Made from aluminium-laminated films, foil liners preserve the quality and integrity of the contents inside the bag. They can be customized using various aluminium compounds to meet the specific needs of each application, ensuring optimal performance and protection.

Types of Bulk Bags Construction

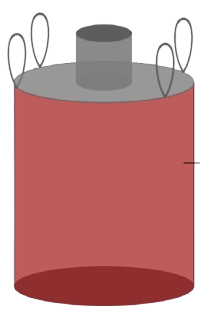

Circular

Circular bags are made from a single tubular piece of fabric that forms all sides, with stitching only at the top and bottom. Despite the tubular design, advanced sewing technology ensures these bags maintain a square shape when filled, debunking the common misconception that they are truly circular. While similar to square or rectangular FIBCs, circular bags hold their shape less firmly when filled compared to other construction types.

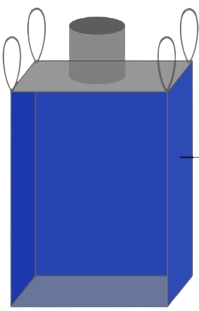

4-panel

4-panel bags are made from four individual pieces sewn together to create a square structure. When filled, they maintain a square shape, similar to other FIBC types. 4-panel bags typically hold their shape better than U-panel bags, which in turn, outperform circular bags. The main drawback of 4-panel bags is the extensive stitching required, which can lead to more potential failure points. Despite this, 4-panel bags are ideal for storage due to their stability when filled.

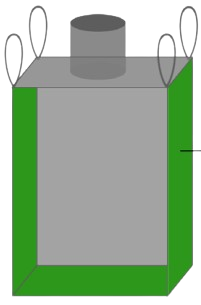

U-panel

U-panel bags feature a design with three body panels: a main panel forming the bottom and two sides, plus two additional panels for the remaining sides. When filled, they maintain a square shape, especially with baffles. Known for their high safe working loads (SWLs) and durability, U-panel bags are a popular choice for bulk packaging.

Lamination vs unlaminated

Lamination

Before a bag is sewn together, an additional polypropylene film is applied to seal the small gaps in the poly weaves, improving performance. This film can be added to either the inside or outside of the bag, with the inside application being the most common. This internal coating helps prevent products like powders from getting stuck in the weave during discharge.

To check if a bag is coated, press the weave together—if it doesn’t spread apart easily, the bag is likely coated. Coated bags provide enhanced protection against contaminants like dust, moisture, and dirt, making them ideal for environments such as warehouses, construction sites, and manufacturing facilities. They offer a moisture barrier and protect stored or transported materials. For powdered products, coated bags minimize the risk of spillage, ensuring a cleaner and more efficient discharge. Coated bags are particularly beneficial for packing small granular or powdered products.

Unlamination

Flexible Intermediate Bulk Containers (FIBCs) are typically made by weaving strands of polypropylene. Due to their weave-based construction, fine materials, such as fine sands or powders, may seep through the weave or sewing lines.

When packing powders in an uncoated bag, striking the side of a full bag can cause a cloud of product to escape. Additionally, the weave of an uncoated bag allows air and moisture to pass more easily through the woven polypropylene, potentially affecting the contents. For enhanced protection, coatings can be applied to prevent product loss and exposure to environmental elements.

Types of Loops

Corner Seam Loops

Loop over loop lift loops, also known as corner seam loops, are among the most widely used types of lift loop construction for FIBCs (Flexible Intermediate Bulk Containers). This construction style features lift loops sewn directly into the seams of the bag, providing a secure and efficient means of lifting.

One of the key advantages of loop over loop construction is its compatibility with forklift lifting. The bag is designed to be lifted by a forklift using all four loops simultaneously, ensuring a balanced load. However, it’s important to note that this process can be more intricate and time-consuming compared to other loop designs.

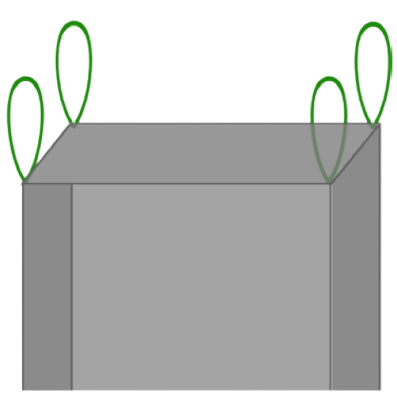

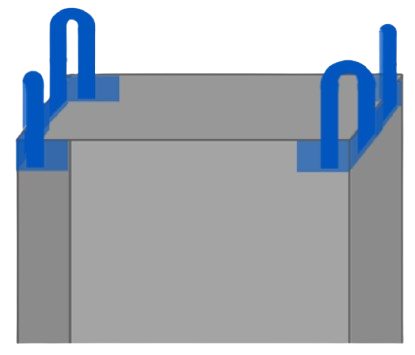

Cross corner loops

Similar to loop over loop lift loops, cross-corner loop bags are designed with lift loops positioned at each corner of the bag. However, in the case of cross-corner loops, the loops are sewn into eight points at opposite corners, rather than directly into the seams. This design is available for all construction types, including circular, 4-panel, and U-panel bulk bags.

One of the standout benefits of cross-corner loop bags is the way they position themselves when filled. These loops are designed to ensure that the lift loops remain upright at all times, making it easier for forklift operators to grab and lift the bags. This upright stance helps reduce bag handling times and enhances overall efficiency in material handling.

Types of Bottom Construction

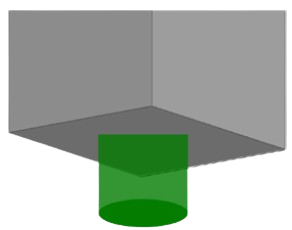

Discharge spout

The discharge spout is located at the bottom of a bulk bag and remains sealed until you’re ready to discharge the product. This spout provides a controlled, direct, and efficient way to release materials without damaging the bag. Available in various sizes, discharge spouts can be customized to suit your specific needs. As the most commonly used discharge option, they offer reliable and secure product release.

Flat bottom (no discharge)

Flat bottom bulk bags feature a simple, single layer of woven polypropylene material as the bottom of the bag. Unlike other designs, flat bottom bags do not include a built-in discharge option and require alternative discharge methods for use. These bags are ideal for applications where other discharge systems are needed.

5:1 vs 6:1 Safety Guidelines

5:1 bulk bag

Most woven polypropylene bulk bags are designed for single use and have a 5:1 safety factor ratio (SFR), meaning they can hold up to five times their rated safe working load (SWL). However, it is important to note that exceeding the SWL is unsafe and not recommended, even though the bag is rated to withstand five times the load. Always adhere to the bag’s rated capacity for optimal safety.

6:1 bulk bag

Some woven polypropylene bulk bags are designed for multiple uses and are rated with a 6:1 safety factor ratio (SFR), meaning they can hold up to six times their rated safe working load (SWL). However, like 5:1 SFR bags, exceeding the SWL is unsafe and should be avoided.

While these bags are built for multiple uses, they must be handled with care. To ensure safety, multiple-use bags should be part of a closed-loop system. After each use, the bag should be cleaned, reconditioned, and qualified for reuse. Additionally, it should be used consistently for storing or transporting the same product in the same application.

Types of Top Construction

Duffle top

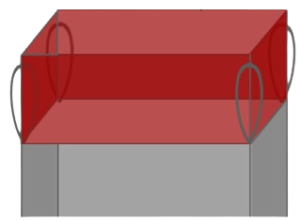

Duffle Top FIBCs are ideal for quick filling applications, featuring a design that opens outward for fast and easy filling. Once filled, the duffle top can be closed and tied to securely transport and store the load. This design is highly effective for efficient packing and safe handling.

Spout top

Spout top FIBCs are among the most commonly used bulk bags, offering a reliable solution for controlled filling. Designed to work seamlessly with most filling equipment, spout top bags ensure efficient and precise product filling. The spout can be securely closed and tied to safely transport or store the load.

Open top

Open top FIBCs are perfect for quick filling applications, providing easy access for fast loading. Typically paired with a flat or spout bottom, these bags are widely used for materials such as building supplies, scrap products, and lawn and garden applications. Their versatile design makes them ideal for handling a variety of bulk goods.

Specific Bulk Bags

Food Grade

Food grade bulk bags are produced in top-tier BRC certified facilities, adhering to the stringent standards set by the Global Food Safety Initiative (GFSI) and industries such as food, chemical, and pharmaceutical sectors. Made from 100% virgin polypropylene resin, these bags meet FDA food grade requirements, ensuring safe and reliable packaging for food products.

UN Certified

Transporting and storing hazardous materials requires specialized solutions due to strict regulations and safety concerns. UN Certified Bulk Bags are specifically designed and certified to safely transport and store hazardous or potentially hazardous materials. Manufactured, tested, and certified to meet rigorous standards, these bags are ideal for handling goods in environments at risk of fire, explosion, chemical burns, toxic contamination, or environmental damage.